ShubTechCNC

our services

Fabrication

The construction of products utilizing a combination of typically standardized parts and one or more distinct procedures is known as fabrication. For instance, steel fabrication involves creating metal structures through a variety of techniques, including cutting, bending, and assembling.

Heat Treatment

A method called “heat treatment” is used to change a material’s physical characteristics for the better. Material is typically heated during a heat treatment procedure to a target temperature at which its physical properties change. It is then cooled gradually after that.

Milling

Using a milling cutter to remove material from a work item is known as milling. The work piece forms chips as a result of shear deformation, which occurs when the cutter is perpendicular to its axis.

Drilling

A drill bit is spun to create a circular cross-sectional hole in solid materials during the drilling process. The drill bit is often a multi-pointed, rotating cutting instrument. While rotating at speeds ranging from hundreds to thousands of revolutions per minute, the bit is forced against the workpiece.

Surface Grinding

Surface grinding is a type of finishing that involves removing impurities and the oxide layer from work piece surfaces in order to smooth the flat surface of metallic or nonmetallic materials and give them a more refined appearance. This will also produce the desired surface for the intended use.

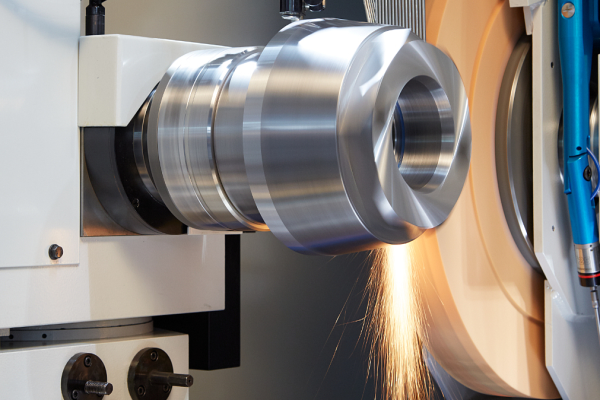

Cylindrical Grinding

The metal piece is positioned between two centres, known as the head and tail stocks, during the cylindrical grinding operation. The cylinder revolves in one direction when the machinist moves the machine. The grinding wheel then begins to move at a different speed and in the opposite direction to begin grinding.

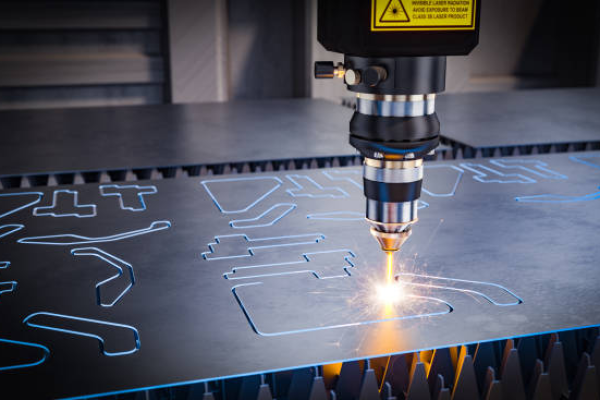

Laser Cutting

To melt material in a specific location, a focused laser beam is used in the primary thermal process of laser cutting. The molten material is ejected and a kerf is made using a co-axial gas jet. By moving the laser beam or workpiece while using a CNC, a continuous cut is created.

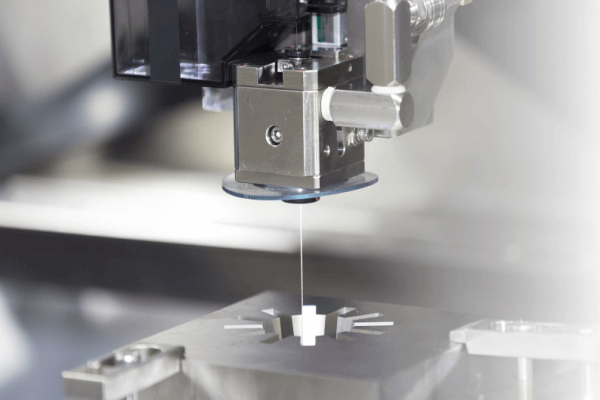

Wire Cut

Millions of sparks fly as a result of a current being sent between the wire and the workpiece in the wire cutting machine. As a result, the sparking produces heat at a temperature of around 15,000 degrees Fahrenheit, which is hot enough to melt away minute pieces of the material and produce precise cuts and complicated forms.